CUSTOMER-SPECIFIC TESTING OF FABRIC AND WORKWEAR

The main advantage of customer-specific testing of fabric and Flame Retardant workwear is that it delivers tailored solutions precisely suited to each unique environment. In some cases, the results from these tests can even lead to the development of new product ranges, such as when Cantex WS was created to enhance protection in the metallurgy industry.

Another significant advantage is that customers gain a clear understanding of how their Flame Retardant workwear protects against their specific risks. It becomes evident how different options perform in comparison. This helps the customer to understand the differences between garments and fabrics - even if their certified standards looks similar on the certificate.

Advantages for Tranemo

For Tranemo, customer-specific testing provides us with deeper insights of how to protect workers in the industry sectors we serve. By testing our products in real industrial environments, for chemicals or molten metal, we receive valuable feedback that we can use to further improve our workwear. We incorporate these insights into our internal training programs through the Tranemo Safety Academy, in which the entire Tranemo Group, including subsidiaries, participates. Our goal is to continually enhance protection to reduce the risk of injuries in the workplace.

Why we do it

Our goal is to ensure that no one is injured in accidents that could have been prevented with the right protective clothing. To achieve this, specific testing is essential since all industries have their own unique conditions. Cooperation with laundries and logistics regarding re-impregnation is also crucial, especially to meet EN 13034 chemical protection standards. Tests are conducted not only at the customers’ sites but also at laundries to ensure that protection remains intact after washing and handling. This is an important complement to the standards that the garments are certified against.

"Customer-specific testing provides us with deeper insights of how to protect workers in the industry sectors we serve."

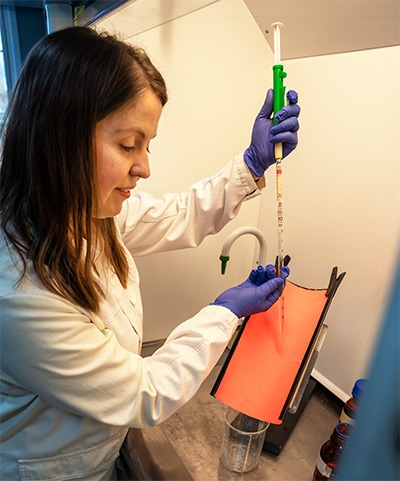

Our Fabric Quality Manager accompanies and provides technical support to the sales team for customised fabric testing in real-life settings. This approach offers numerous advantages, ensuring that our solutions are not only theoretically good but also practically effective. By doing this we ensure the safety of our customers and delivering the best protection.

Below, you can read about some of the tests and results we have conducted.

Nitric acid

Through fabric testing in collaboration with one of our larger customers, we had come to the conclusion that our Tera TX fabric offers the best protection against nitric acid. Still our customer had problems with acid leaking inside the garment. We discovered that the seams on reflective bands allowed the acid to penetrate to the backside of the garment. By switching to a thread that did not transport the acid, we were able to increase protection time from 8 seconds to over 3 minutes, giving workers enough time to reach a safety shower and remove contaminated clothing. This significant improvement dramatically enhanced worker safety.

Chromic acid

One customer required protection against splashes of chromic acid. Multiple fabrics were tested, and Tera TX emerged as the best option. The tests were conducted on fabrics with both PFAS and PFAS-free finishes to ensure that the level of protection remains consistent, even when transitioning away from PFAS.

Radiant heat

Another customer needed higher protection against radiant heat. Tests led to the decision to use two layers of fabric from the knee down. This work is a still ongoing wear test, and we look forward to the final results.

TRANEMO TIPS:

» Perform a thorough risk analysis.

» Keep in mind that a “one single solution” (multinorm) often is impossible to make.

Carefully consider which risks are necessary to include in your risk assessment. For example, if both high visibility (EN ISO 20471) and chemical protection (EN 13034) are required, the reflectors on the hi-vis garments may reduce the protection against chemicals. It is challenging to design garments that combines all the requirements of EN 13034, EN ISO 20471, EN ISO 11611, and EN ISO 11612.

» We can either send fabric samples or conduct the tests on-site with you.

» Contact Tranemo for advice on your risk analysis or if further testing is needed.