Sustainable production of Flame Retardant workwear in Europe

European production of Flame Retardant workwear is a cornerstone of Tranemo's business, with as much as 90% of our manufacturing taking place in Europe. We collaborate closely with selected suppliers to develop sustainable technical textiles and Flame Retardant workwear that meet our stringent requirements for functionality, durability, and safety. We see a strong future for European manufacturing, with continued innovation leading the way in sustainable workwear development.

The benefits of Swedish Flame Resistant workwear manufacturing

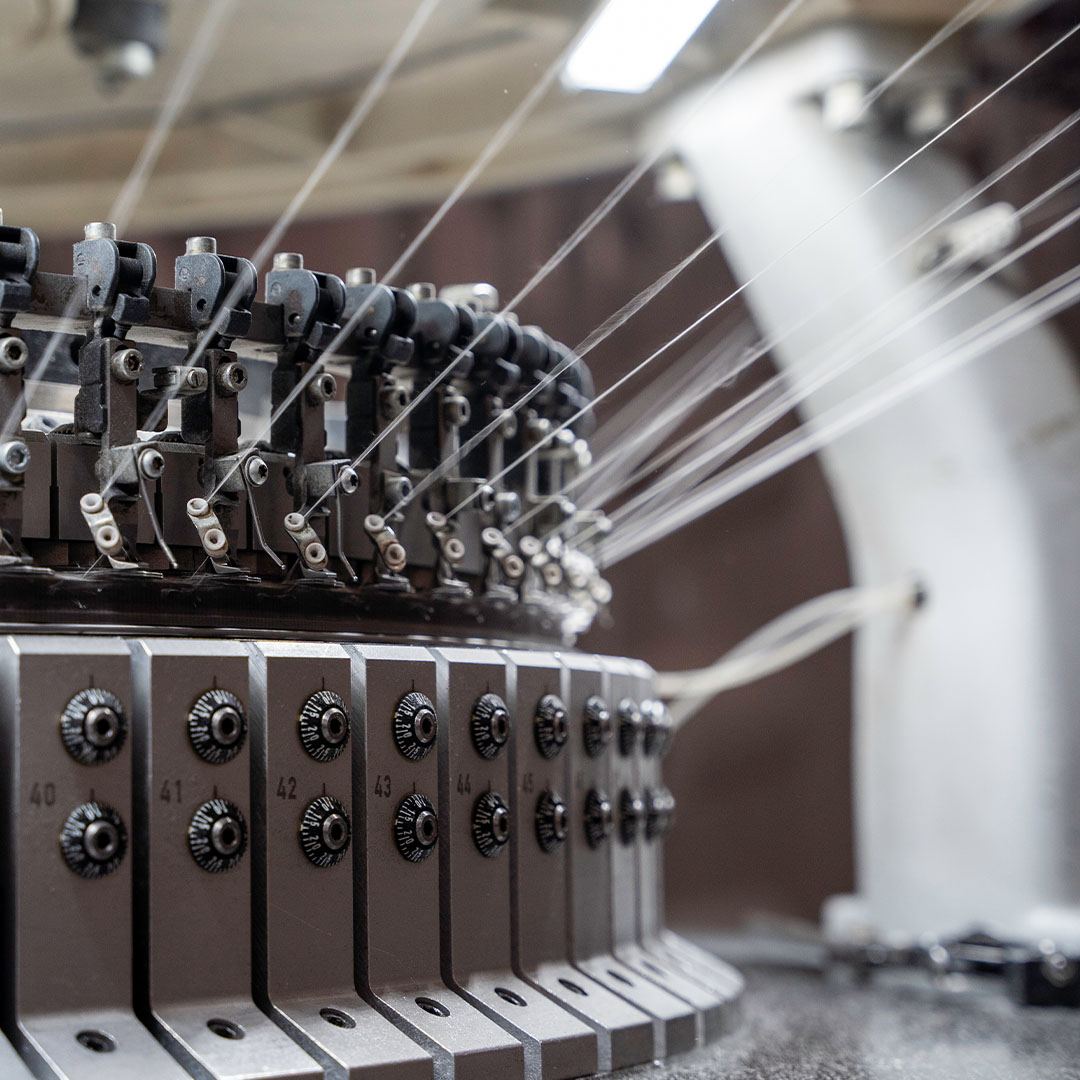

Manufacturing Flame Retardant workwear in Sweden provides significant competitive advantages, particularly in terms of proximity and flexibility. As the production manager at our Swedish knitting company explains: “The ability to quickly adjust patterns and materials is crucial. This flexibility enables us to respond swiftly to customer needs and develop customised solutions for Flame Resistant knitted workwear."

Our supplier is renowned for its advanced automation, which reduces production costs without compromising on quality. Their technical expertise enables early testing of new fibres and materials, allowing us to be among the first to introduce innovative solutions to the market. This combination of automated processes and technical know-how positions us as a leader in the development of Flame Retardant textiles.

Challenges of Flame Retardant and sustainable materials

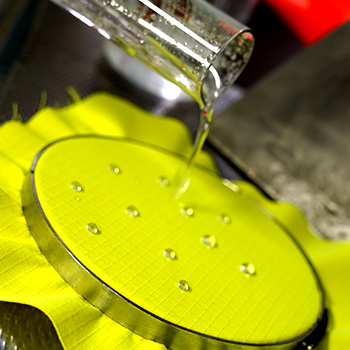

Producing Flame Retardant and durable technical textiles presents specific challenges, particularly regarding material durability and functionality. For instance, fibres used for flame retardancy often shrink more than other materials, requiring carefully crafted patterns and tailored designs.

”It’s about finding the right balance between flame retardancy, shrinkage, and durability." explains the production manager.

By selecting the right materials and employing advanced manufacturing techniques, we have created Flame Retardant workwear that maintains its functional properties, even after repeated washing. Durability and functionality are central to all our products.

Collaboration and Innovation

At Tranemo, we believe that close collaboration is essential to continuously develop and certify Flame Retardant workwear. Regular meetings between product development, production, and purchasing teams enable us to swiftly address both operational and strategic challenges.

This innovative approach to collaboration keeps us at the forefront of sustainable Flame Retardant textile development, providing customised solutions tailored to our customers’ specific needs.

The future of Swedish manufacturing of Flame Retardant workwear and technical textiles

The future of Swedish Flame Retardant workwear manufacturing is promising. Demand for soft, comfortable, and durable knitted workwear is rising, alongside an increasing focus on sustainability and environmentally friendly alternatives. For example, we have reduced the use of farmed cotton by incorporating 50% recycled cotton into our Flame Retardant fabrics. This shift contributes to a more sustainable and eco-friendly supply chain.

Additionally, we are actively testing and evaluating fibres that could replace cotton, further advancing sustainable manufacturing practices. We are confident that Flame Resistant knitted workwear will gain popularity, and we remain committed to developing flexible, sustainable, and innovative products to meet this growing demand.